New Products

-

Custom CNC Milling Machining Parts Perforated Sheet Metal Fabrication Aluminum Sheet Metal

Custom CNC Milling Machining Parts Perforated Sheet Metal Fabrication Aluminum Sheet Metal

-

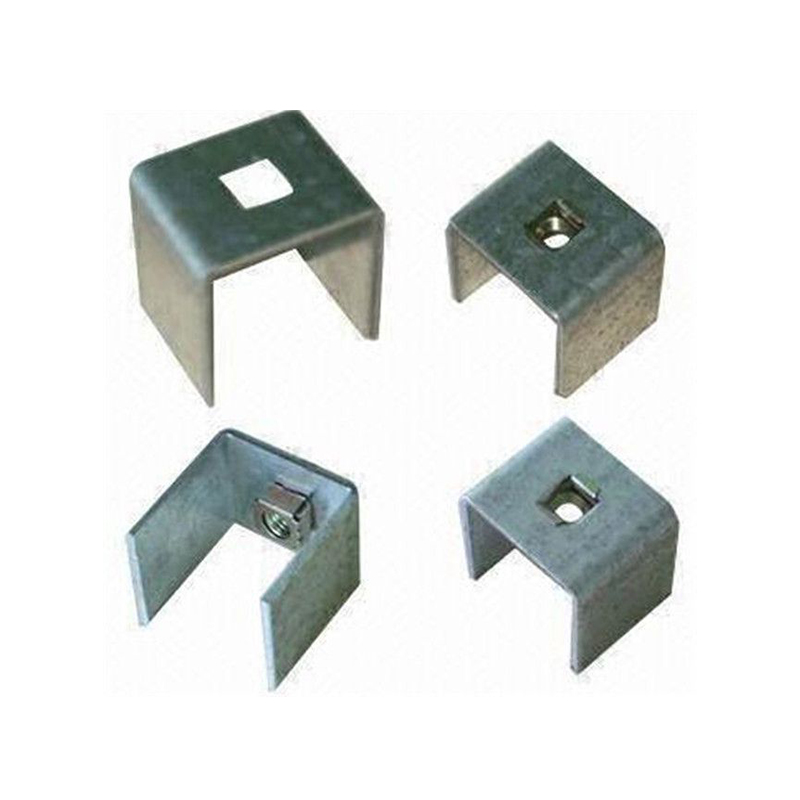

Factory manufacture china product good quality sheet metal precision metal stamping metal stamping small parts

Factory manufacture china product good quality sheet metal precision metal stamping metal stamping small parts

-

China factory custom sheet metal fabrication

China factory custom sheet metal fabrication

-

Sheet Metal Fabrication

Sheet Metal Fabrication

-

OEM custom factory precision metal stamping parts fabrication punching bending electrical auto sheet metal stamping

OEM custom factory precision metal stamping parts fabrication punching bending electrical auto sheet metal stamping

Injection Molding

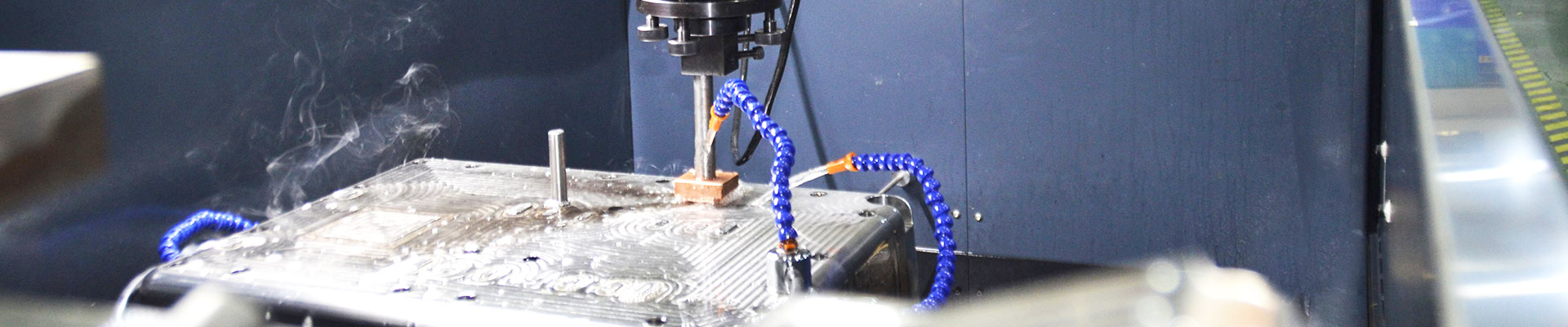

Need mold making supplies for large quantities of production parts? Looking for a more cost effective and time efficient way of manufacturing parts

Send Inquiry

Product Description

Need mold making supplies for large quantities of production parts? Looking for a more cost effective and time efficient way of manufacturing parts? Don’t miss our injection molding services! At MIMCNC, we provide high quality and affordable injection molding for prototypes and production parts with quick turnaround times.

What Is Injection Molding & Mold Making

Injection molding & injection moulding is the most commonly used manufacturing process for manufacturing plastic parts. It refers to the method that under a certain temperature, the plastic material completely melted by screw stirring is injected into the mold cavity with high pressure, and then cooled and solidified to obtain the injection molded product. This method is really cost effective and it’s suitable for the mass production of complex shape parts. There are mainly six stages: mold closing, glue injection, pressure maintaining, cooling, mold opening and product removal. Molding also has the highest variety of materials, colors, and configurations when compared to CNC machining or even 3D printing. Beyond materials, injection molded parts can have custom cosmetics, polishes, or surface textures.

Advantages of injection molding & moulding services:

Good dimensional accuracy.

High productivity, easy to realize automatic operation.

Excellent surface finish.

Large volume production available.

little need to finish parts after molding.

Automation to save manufacturing costs.

Excellent repeatability and flexibility.

Injection molding produces low scrap rates relative to traditional manufacturing processes like CNC machining.

Minimize the material waste.

Tooling & Injection molding applications:

The parts manufactured by mold making service are used for building and construction, food and beverage, windows and doors, automotive, household appliance, electronics, communications and more industries, car molding, medical molding, and bumper molding would be a key part.

Common plastic injection molding materials:

Polycarbonate, Polyoxymetheylene (POM), Polystyrene (PS), Acrylonitrile Butadiene Styrene (ABS), Polypropylene (PP), Polyethylene (PE), Thermoplastic Polyurethane (TPU), Thermoplastic Rubber (TPR).

Different types of injection moulding processes:

Die casting

Metal injection moulding

Thin-wall injection moulding

Injection moulding of liquid silicone rubber

Reaction injection moulding

Micro injection moulding

Gas-assisted injection moulding

Cube mold technology

Tooling & Mold Making Service Online – Best Injection Molding Manufacturer Company In China

MIMCNC is one of the best mold makers in China, offering molding solutions for every industry, including medical injection molding, electrical injection molding, automotive injection molding and more. In order to meet our clients’ large demand for plastic parts, we cooperate with reliable partners to offer injection molding services, which can make up for your one-stop requirements for plastic prototype and mass production. Our main services offering include insert-molding, overmolding & two color injection molding, as well as with CNC machining. With more than 10 years of experience, we are able to produce custom affordable injection molding parts plastic, insert molding parts and overmolding parts according to customers’ specifications, drawings or samples. We own advanced techniques, highly skilled staff that employ superior tooling and high pressure injection molding processes to ensure that the mold parts are of the cheapest price and highest quality. Whether you need rapid tooling, mass production mold making with tight tolerances, our team of experienced specialists can offer a cost-effective solution at each stage. Contact our expert team and get a price for your tooling/mold making service, we will quote you a plastic injection mold price in 24 hours!

Why Choose Our Injection Mold Making Services

There are huge numbers of mold making companies. Why should you choose us as your tooling & injection molding supplier? Here are the reasons:

High production capability and competitive prices for injection molding service are offered.

We have rich injection mold manufacturing experiences for over 10 years and earned a good reputation.

Exceptional customer service and communication.

Multiple of plastic injection mold designs & types – 3D printed injection mold, Insert mold, Overmold & Two-color mold (work in with CNC machining service) are available to meet custom needs.

Do precision injection molded parts manufacturing according to your drawings or samples.

Finish the parts with service of mold making in time to provide the strongest support for your R&D projects.

Our automated quoting, design analysis, and manufacturing process allows us to ship injection molding orders in as fast as 1 day.

We have advanced production equipment and facility, technology and materials to make the most precise injection mold plastic as well as great aspect.

We have the most experienced engineers and tooling partners that will really make a difference in your lead times, costs and final quality.

Cooperative Supplier Collaboration Project

In order to realize our customers’ large demand for plastic parts

We and our partner provide this service together

Can make up for your one-stop needs for plastic proofing and mass production

Injection Mold Designing & Making – How To Make Injection Mold

There are many factors to consider for injection molding, but part design for the injection molding is critical. Getting it right could mean lower entry cost, high production quality, shorter cycle time, and quick assembly. As a source of experienced engineers and product designers, we have an individual or a team of professionals who can help you develop injection molded parts from scratch. Our team of injection mold design engineers specialize in drawing with CAD, CAE, CAM, commonly using SOLIDWORKS, PRO ENGINEER, UNIGRAPHICS, and MOLD FLOW analysis software.

What’s more, we use 3D printing method to make mold parts and this mold making method helps you reduce the cost and reduce the labor intensity in terms of improving productivity and ensuring product quality. So choose us and you can get the best quality 3D printed injection mold.

Capabilities Of Injection Molding Service At MIMCNC

1.Custom Insert Molding

MIMCNC also offers insert molding as part of its injection molding capabilities that works especially well for parts that have threaded holes. With our custom insert molding service, you can make parts all at once instead of having to do assembly after the fact. And insert molding service will help you reduce costs, lower the size and weight for the part, and improve reliability. Insert molding materials including ABS, PPS, PS, PSU, PEEL, Liquid Silicone Rubber, Polypropylene, Polycarbonate, PMMA, PEI, PPA, LCP, etc.

How does insert molding work?

It uses a preformed part that is loaded into a mold where it is then overmolded with a thermoplastic resin to create a final component. When the run is complete, parts are boxed and shipped shortly thereafter.

Advantages of our insert molding service:

Durability: Metal inserts will guarantee the function of threads and mitigate wear and tear over the part’s life.

Strength: Because it’s a “one-shot” process, insert molding can produce stronger parts than overmolding and other processes.

Creating production parts: Insert molding is great for creating prototypes and production parts.

2.Overmolding Service

Overmolding is a multi-step injection molding process where two or more components are molded over top of one another. It’s sometimes referred to as two-shot molding because it is a two-step process. Using overmolding service allows us manufacture products with multiple materials and/or colors relatively simply and can be used for a range of applications including medical, automotive, military and more. MIMCN has the expertise to make sure your overmolding project is a success. Work with us to create the ideal solution for your exact needs. No matter what the specifications of your project, we will meet the expectations of your next overmolding project!

Injection Molding Surface Finishes & Textures

Injection molded parts have various of surface finishes. Plastic parts and parts made of other materials can be given various types of finishes for aesthetic or functional purposes. Different types of injection molding surface finishes can be used to certain processes to produce a new product with a different texture, look, and feel.

There are many finishing options for injection molding when requesting an injection molding quote on MIMCNC include:

Custom color matching

SPI finishes

Threaded inserts

Pressure blasting

Polishing

Sandpaper

Grit stone

Diamond buffing

Bead blast

Pad printing

Laser Engraving

Mold texturing

Basic assembly

Choose from a wide selection of finishing options for injection molding that strengthen parts, enhance injection molded parts appearance, provide customization and other benefits!