New Products

-

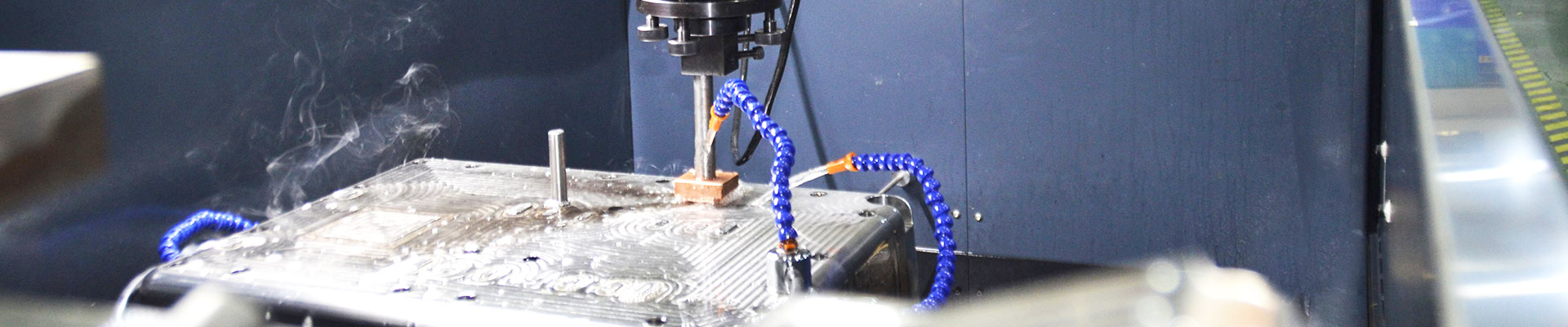

Custom CNC Milling Machining Parts Perforated Sheet Metal Fabrication Aluminum Sheet Metal

Custom CNC Milling Machining Parts Perforated Sheet Metal Fabrication Aluminum Sheet Metal

-

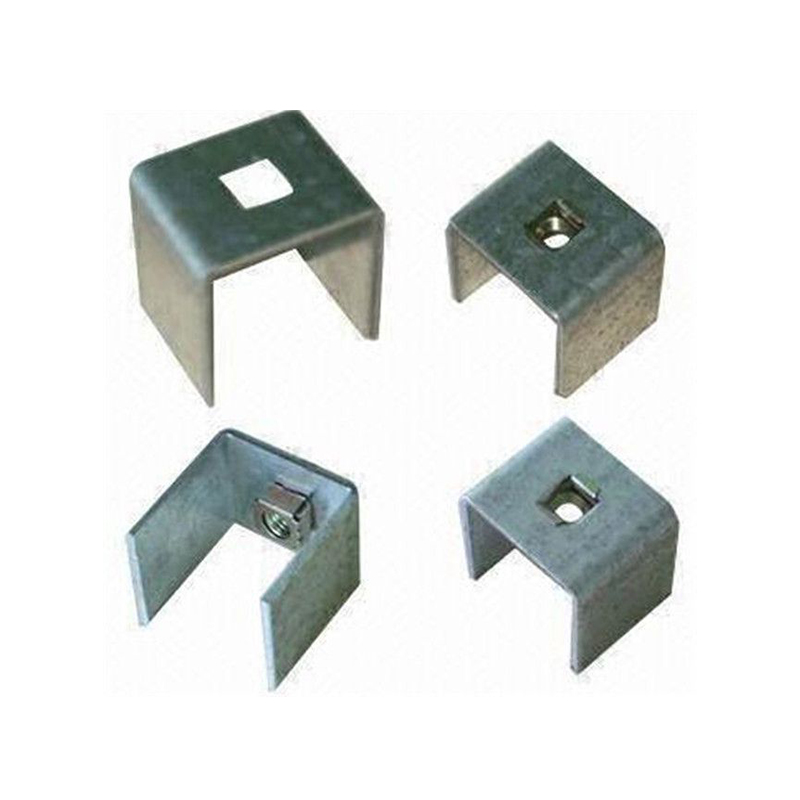

Factory manufacture china product good quality sheet metal precision metal stamping metal stamping small parts

Factory manufacture china product good quality sheet metal precision metal stamping metal stamping small parts

-

China factory custom sheet metal fabrication

China factory custom sheet metal fabrication

-

Sheet Metal Fabrication

Sheet Metal Fabrication

-

OEM custom factory precision metal stamping parts fabrication punching bending electrical auto sheet metal stamping

OEM custom factory precision metal stamping parts fabrication punching bending electrical auto sheet metal stamping

Sheet Metal Fabrication

Custom Sheet Metal Fabrication Services – Rapid Sheet Metal Prototyping Company China If you want to find a cost-effective

Send Inquiry

Product Description

Custom Sheet Metal Fabrication Services – Rapid Sheet Metal Prototyping Company China

If you want to find a cost-effective and rapid sheet metal prototyping solution for your manufacturing needs, MIMCNC can be a good choice for you. Based on extensive experiences and professional expertise, our sheet metal fabrication services are available for both prototypes and low to high volume production runs. Working with MIMCNC, the most advanced fabrication machinery allows us to fabricate end-use sheet metal parts and products in high efficiency while maintaining premium quality, which saves money and time for our clients significantly. A wide range of materials and surface finishes enable us to make the best option for your project, the raw materials including but not limited to stainless steel, aluminum, brass, copper, steel, plastic, etc. Polishing, painting, sandblasting, plating, anodizing, powder coating and more finishing services bring better surface quality for your parts. Our custom sheet metal fabrication service provides durable and affordable sheet metal components that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.

Why Choose Custom Sheet Metal Fabrication Services at MIMCNC?

Capabilities in fabrication, machining and finishing enable us to offer one-stop shopping

Sheet metal fabrication service supplies durable parts for prototype and end-use

A wide selection of material and surface metal finishing or treatment processes

Accurate dimensions and specifications based on your demands and a variety of instruments

Quick free quote within 24 hours and fast turnaround in average one week

Competitive prices and the highest standard quality provide the most economic solution

No minimum order quality. You can order a prototype of thousands of metal parts

Sheet Metal Materials

Sheet metal is a widely used form of raw material, usually 0.006 and 0.25 inches thick sheet used in sheet metal fabrication. Use the sheet metal gauge chart on our site to designate the thickness. Here are some popular sheet metal materials, stainless steel grade 304 is one of the most common options due to its good corrosion resistance, formability and weldability. If your applications are pumps, valves, chemical equipment, and marine product, grade 316 is recommended. For aluminum, the four most common aluminum grades available as sheet metal are 1100-H14, 3003-H14, 5052-H32, and 6061-T6. Brass is also widely used in the sheet metal fabrication process, it has more strength, corrosion resistance, and formability when compared to copper while retaining its conductivity.

Aluminum: Al 5052, 6061

Copper: C101, C110, brass (C260)

Stainless Steel: SS 301, 304, 316/316L

Steel: low carbon steel

Types of Sheet Metal Finishes

If you require special treatment or post-processing for your parts, please check out the following sheet metal finishing options. If you can’t find what you want, welcome to send your inquiry to us, a wide range of surface finishes are available at mimcnc, a fast quote will be offered. Custom materials finish making your sheet metal fabricated parts achieve improved appearance and performance.

Bead Blast

Anodize

Plating (Nickel Plating, Silver Plating, etc.)

Powder Coating

Chromate Conversion Coating

Custom finishing services

Sheet Metal Fabrication Sizes & Tolerances

1.Dimensions of sheet metal fabrication parts

Size: 47 in. x 119 in. OR 1,193.8mm x 3,022.6mm (max)

Bend length: 10 ft. OR 3.048m (max)

Flat part: 0.5 in. x 0.5 in. OR 12.7mm x 12.7mm(min)

Formed part: 1.5 in. x 1.5 in. OR 38.1mm x 38.1mm (min)

2.Sheet metal fabrication tolerances of different features for reference.

Bends: +/- 2 degree

Offsets: +/- 0.024 in. (+/- 0.608mm)

Hole Diameters: +/- 0.010 in. (+/- 0.254mm)

Edge to Edge/Hole; Hole to Hole: +/- 0.010 in. (+/- 0.254mm)

Hardware to Edge/Hole:+/- 0.020 in. (+/- 0.508mm)

Hardware to Hardware: +/- 0.030 in. (+/- 0.762mm)

Bend to Edge: +/- 0.020 in. (+/- 0.508mm)

Bend to Hole/Hardware/Bend: +/- 0.030 in. (+/- 0.762mm)

Features Separated By Two or More Bends: +/- 0.060 in. (+/- 1.524mm)

What is Sheet Metal Fabrication?

Sheet metal fabrication involves a set of manufacturing processes of forming either prototypes or end-use parts from sheet metal. Cutting, bending and punching are commonly used. So typical tools used in sheet metal fabrication including brakes, punches and dies. The type of machine used depending on the material, the gauge of the sheet, and other factors. Most sheet metal components require a combination of forming processes, but this will not increase the price greatly. The 3D CAD design will be converted into a special machine code, which controls the machine to execute cutting operation precisely and fabricate the final part. Sheet metal parts are known for their durability and economics, which makes them the perfect choice for lots of end-use applications.

How Does Sheet Metal Fabrication Work?

The common sheet metal fabrication process starts with material removal, during the stage, the raw material is cut to the desired shape by different cutting tools. A variety of subtractive machining processes can complete the operation. The second stage of sheet metal fabrication is material deformation. The piece that has been cut needs to be formed into a 3D shape with the forming process like bending. No materials are removed during the stage. The last step is to assembly several pieces into a complete product if there are multiple parts. Sometimes, surface treatment is needed to provide a better surface finish.

What is a Sheet Metal Prototype?

A sheet metal prototype is an early sample, model, or release of a metallic product used to test a concept or process. Rapid sheet metal prototyping service develop prototypes based on designs submitted by customers and test the product before it enters the market. This can minimize the loss and reduce the risk. Various sheet metal prototyping processes at MIMCNC can design your orders in hours and suit your varying needs.

Advantages of Sheet Metal Fabrication

High malleability and durability to withstand pressures and last a long time

Reduced tooling time to cut or bend the metal, save on the production cost

Easy to handle custom simple or complex projects, whether prototypes or large scale

Standard sheet metal thickness used in laser cutting or bending

Inexpensive but high-quality end-use sheet metal products

Improved construction quality, easier to maintain

Sheet metals can be formed into virtually any desired shape

Sheet metal parts are recyclable and not harmful to the environment

High strength and high resistance to corrosion, sun, and moisture