New Products

-

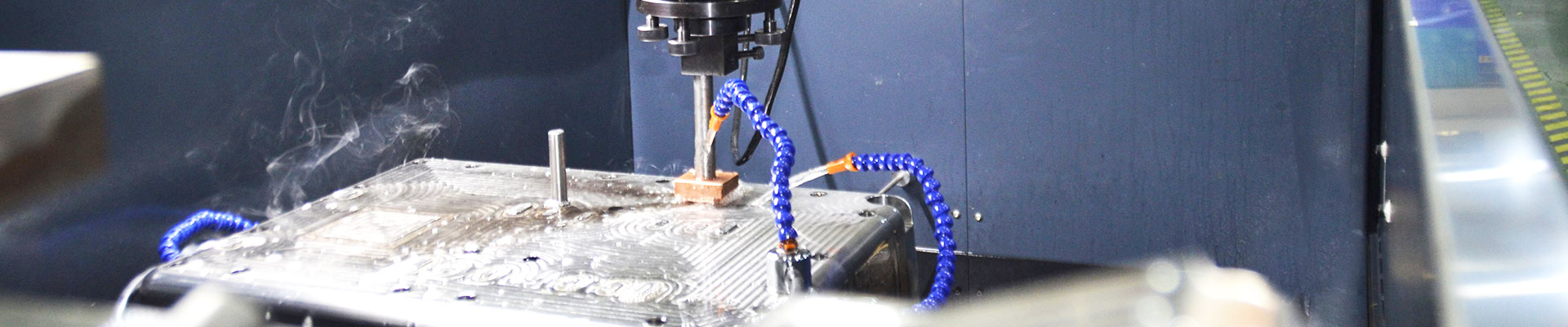

Custom CNC Milling Machining Parts Perforated Sheet Metal Fabrication Aluminum Sheet Metal

Custom CNC Milling Machining Parts Perforated Sheet Metal Fabrication Aluminum Sheet Metal

-

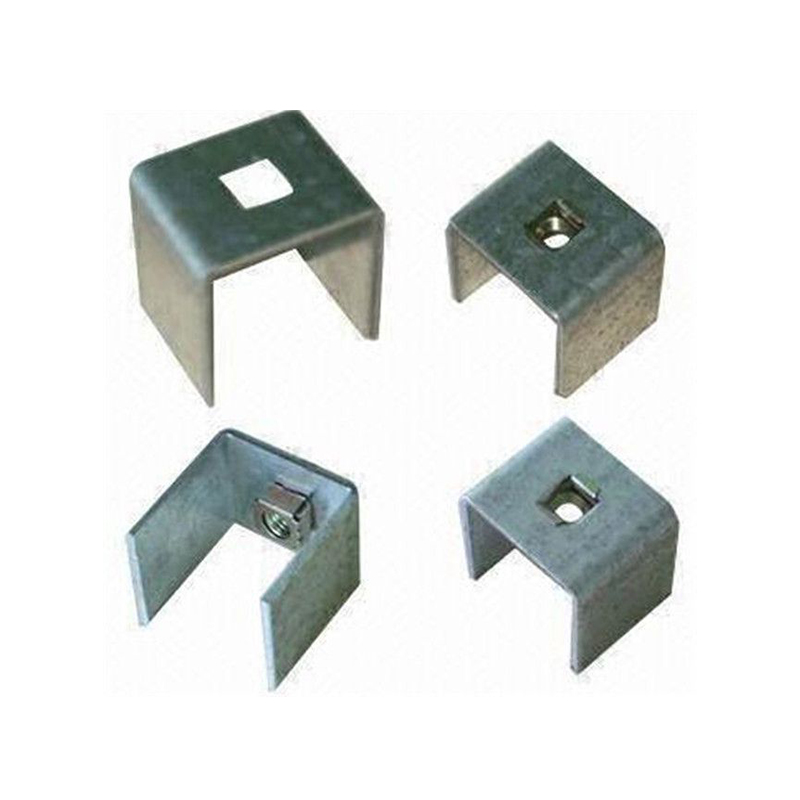

Factory manufacture china product good quality sheet metal precision metal stamping metal stamping small parts

Factory manufacture china product good quality sheet metal precision metal stamping metal stamping small parts

-

China factory custom sheet metal fabrication

China factory custom sheet metal fabrication

-

Sheet Metal Fabrication

Sheet Metal Fabrication

-

OEM custom factory precision metal stamping parts fabrication punching bending electrical auto sheet metal stamping

OEM custom factory precision metal stamping parts fabrication punching bending electrical auto sheet metal stamping

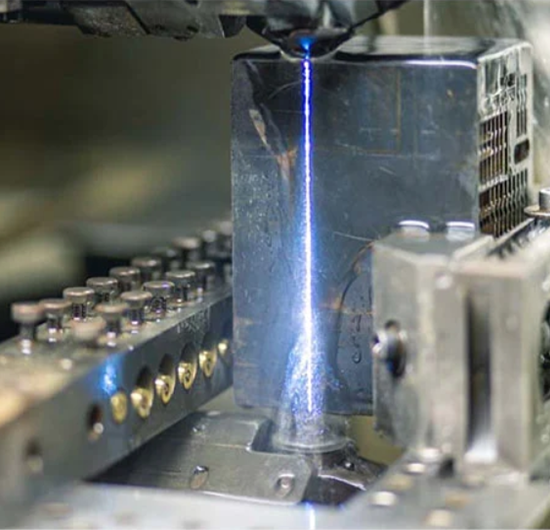

Wire Edm Machining

Wire EDM Machining Services – Wire EDM Parts & Electric Discharge Machining Company MIMCNC (mimcnc com) is a specialist that can fabricate industrial parts and custom machined parts using a wide variety of manufacturing techniques

Send Inquiry

Product Description

Wire EDM Machining Services – Wire EDM Parts & Electric Discharge Machining Company

MIMCNC can fabricate industrial parts and custom machined parts using a wide variety of manufacturing techniques. With Wire EDM Machining Services at MIMCNC, you can get your wire EDM parts in a much faster and more accurate way when compared to conventional machining. Our newest wire EDM machines can meet your needs of high volume while maintaining high repeatability, top quality, and tight tolerances. Over the past years, we have earned a good reputation for producing custom parts with reasonable pricing and on-time delivery, while also being capable of working with electrical discharge machining equipment to provide wire cut EDM parts and services for our customers. Our EDM services offer experience and excellence in all types of EDM machining. Fill out the form below today to receive a free quote!

Why Choose MIMCNC Wire EDM Machining Services

Quantity Flexibility: From prototypes to low- and high-volume production, we can meet your requirements with exact specifications.

Quality Assurance: Our team of highly skilled workers and strict quality control and inspection will ensure the quality of the final parts.

Professional Service: Electric Discharge Machining services at MIMCNC will maintain integrity, consistency, productivity, and economy.

High Standards: Our purpose is to achieve perfection in wire cut EDM machining through continuous improvement and upgrades to our equipment.

Customer Satisfaction: With fast turnaround, on-time delivery, high quality, competitive prices, and top-quality service, we will work hard to ensure you are satisfied with every order.

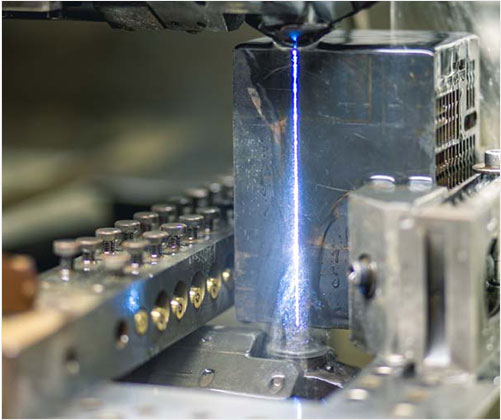

What is Wire EDM?

Electrical Discharge Machining (EDM), also known as spark machining, die sinking, and spark eroding, started with the observations of Joseph Priestley in 1770. Wire EDM process is developed based on electrical discharge machining and forming. Wire cut EDM, as the name suggests, as a thin wire used as the cutting tool. The tool can turn 360 degrees during the cutting process. As a result, it can cut machining workpieces of any shape. At present, wire EDM cutting mostly depends on the phenomenon of similar arc discharge to dissolve metal, which achieves the cutting effect. Therefore, wire cutting can only be used with metal or conductors. Wire EDM is used to accurately cut metal materials for high-precision machining. It is usually used to process block materials (such as molds and gears, precision fixtures) and post-treatment of hardened parts requiring high machining accuracy, rather than cutting sheet materials.

How Does Wire EDM Work?

An electrically charged wire is used in the EDM process, which is the most significant characteristic of wire cutting. So, how does it work?

First, the workpiece to be processed is placed on the workbench. You can cut it from the end of the workpiece, but usually, at the beginning of wire cutting, the starting hole is usually connected to the material to avoid deformation due to the internal stress of the workpiece. When the CNC program starts, the wire moves within the XY plane to cut the part.

When the distance between the workpiece and the wire electrode in the insulating state in the working fluid is within tens of microns, the insulation between them is damaged and spark discharge occurs, resulting in the instantaneous flow of pulse current. In a high-density discharge state called an arc tower, a local high temperature of thousands of degrees is generated and the metal melts.

In addition, the temperature of the working fluid around the arc column immediately rises and vaporizes, causing rapid volume expansion, resulting in an explosion between the workpiece and the electrode surface. This blows out metal debris.

Then, when the pulse current is cut off and flows into the surrounding clean water, the molten metal cools and becomes a fine debris. The debris is washed away, and the insulation between the electrodes is restored again, waiting for the supply of the next pulse voltage.

Through this process, the metal is melted and removed at each voltage pulse and repeated hundreds of thousands of times per second to cut the workpiece by wire cutting EDM.

Benefits of Wire Cut EDM

Avoids damage conventional machining can cause to small parts

Ideal for processing delicate, hard, exotic, or weak materials

Suitable for situations requiring low levels of residual stress

Eliminates the need for post-machining or heat treatment

Reduces the possibility of surface distortion

Achieves a burr-free surface and edge finish

Minimizes unproductive downtime and fast turnaround

What Materials Can Wire EDM Cut?

The EDM wire cutting process has become a popular choice for a wide range of industries. The wire EDM can cut any conductive materials including aluminum, brass, steel, titanium, superalloys, and other alloys. The process can produce machine parts, components, logos, and other metal parts easily. Typically, the electrodes for EDM cutting are made of copper or graphite.