New Products

-

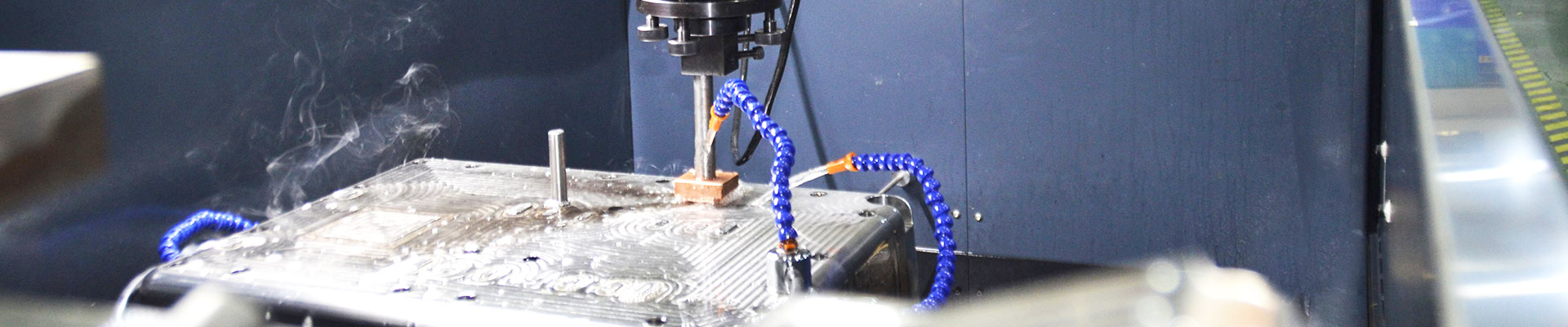

Custom CNC Milling Machining Parts Perforated Sheet Metal Fabrication Aluminum Sheet Metal

Custom CNC Milling Machining Parts Perforated Sheet Metal Fabrication Aluminum Sheet Metal

-

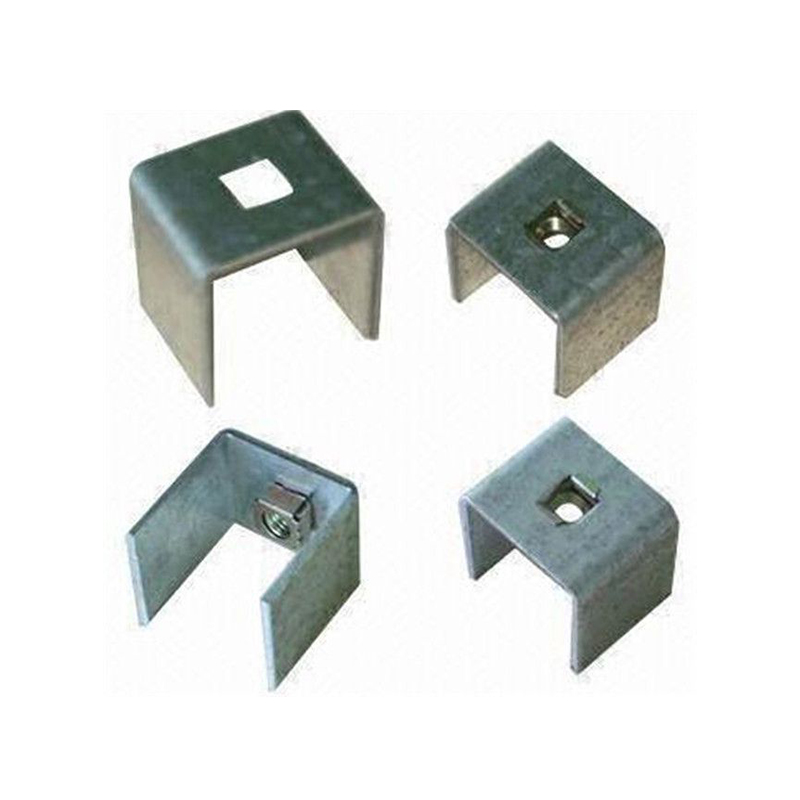

Factory manufacture china product good quality sheet metal precision metal stamping metal stamping small parts

Factory manufacture china product good quality sheet metal precision metal stamping metal stamping small parts

-

China factory custom sheet metal fabrication

China factory custom sheet metal fabrication

-

Sheet Metal Fabrication

Sheet Metal Fabrication

-

OEM custom factory precision metal stamping parts fabrication punching bending electrical auto sheet metal stamping

OEM custom factory precision metal stamping parts fabrication punching bending electrical auto sheet metal stamping

Product Description

CNC Cutting Services Online – CNC Metal & Plastic Cutting Company

MIMCNC is a trusted online CNC services supplier that is able to provide custom cut parts for your project with top quality and fast shipping. With decades of experience and expert capabilities, our CNC cutting services can cut an extensive range of materials using laser cutting, waterjet, and other technologies. According to your requirements and applications, we’ll offer suggestions for the product design, suitable materials, and the most cost-effective methods for CNC cutting and manufacturing. Minimal cost, time and best quality are our focus. Equipped with state-of-the-art facilities and measuring equipment in our factory, CNC metal and plastic cutting now supply CNC cutting parts for several businesses and private individuals, catering both long and short production runs.

Why Choose MIMCNC Cutting Services

Highly trained machinists and skilled engineers can help you create and improve your design.

A broad range of techniques can be performed at our machine shop with efficiency and speed.

With up-to-date manufacturing facilities, our CNC machines work with several materials.

Final CNC custom cut parts with high precision are easily reproducible in a much shorter time.

Prompt reply and communication, we’ll keep you updated throughout the whole production process.

Free online quotes and design feedback to provide effective solutions and suggestions.

What is CNC Cutting

Unlike traditional cutting services, CNC cutting is a subtractive manufacturing method that uses a variety of different cutting technologies combined with computer numerical control software to remove parts of the material block to create specific 2D or 3D shapes. Common CNC cutting machines and tools including laser, water jet, route, plasma, and knife cutting. CNC cutting services provide products for aerospace, automotive, chemical, agriculture, military, defense, and other commercial and industrial applications. CNC cutting is widely used due to its speed, precision and accuracy, as well as little human error. CNC cutting process can be performed alone or with other processes depending on the configuration and purposes.

Types of CNC Cutting – CNC Cutting Technologies & Processes

CNC Plasma Cutting: A plasma cutting torch is usually used cut through various materials such as stainless steel, mild steel, aluminum, brass, and other metals. Plasma cutting is ideal for budget rapid prototyping, large pieces, or extended jobs. It is the most affordable cutting option.

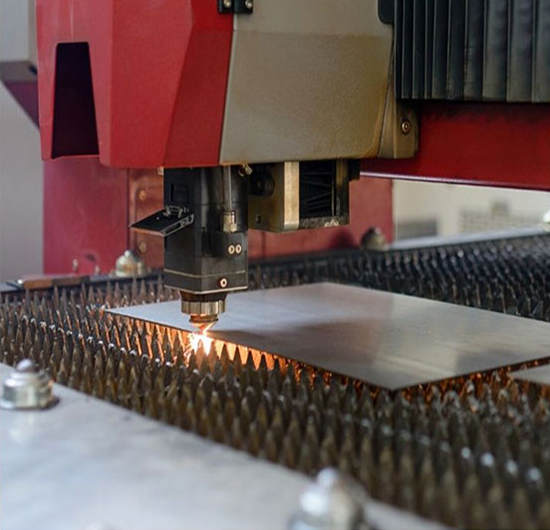

CNC Laser Cutting: A manufacturing process carried out by CNC laser cutters, lasers can cut several materials, including the toughest metals and hardest gemstones, with impressive efficiency. It is also an extremely quick process to cut wood and plastic materials to create excellent cut edge quality and an exceptional level of detail. Laser cutting can produce intricate parts to high tolerances with a smooth surface finish.

CNC Waterjet Cutting: This process uses an ultra-high pressure stream of water to carry abrasive grit, which leaves a precise and smooth cut surface on the workpiece. Water jet cutting is the most versatile method to cut almost any material with good surface quality and no heat affected zone, but it is less efficient compared to the other two cutting techniques.

CNC Cutting vs Laser Cutting, What’s the Difference?

CNC cutting uses Computer Numerical Control devices and specialized tools to produce final parts based on the CAD design or drawing provided by clients. The design will be converted to instructions to the CNC machine, which will then guide the operation of the cutting tool. Laser cutting also applies a CNC system to quite the laser cutting machine, which relies on heat to shape the workpiece. A high-energy light beam is used to burn through the metal material to cut the desired geometry.

What’s the difference between CNC cutting and laser cutting? The major difference between them is how the cutting is performed. A CNC cutting machine cuts through direct physical contact, while laser cutting users a laser to cut through the material, the process requires directing the output of a high-powered laser. Put it simply, CNC cutting involves friction, and laser cutting is achieved by heat.

In addition, CNC cutting is more affordable when compared to laser cutting. The cost of a laser cutter contributes much to this. The precision that can be achieved with laser cutting is also incredible, you can get a level of precision and intricacy that is almost impossible through friction-based CNC cutting. When it comes to surface quality, laser cutters also provide much cleaner edges. And the biggest benefit of CNC cutting is that it can produce diagonal, curved, straight-lined, and more complex shapes easily with CNC programming. It also eliminates the possibility of human error.