New Products

-

Custom CNC Milling Machining Parts Perforated Sheet Metal Fabrication Aluminum Sheet Metal

Custom CNC Milling Machining Parts Perforated Sheet Metal Fabrication Aluminum Sheet Metal

-

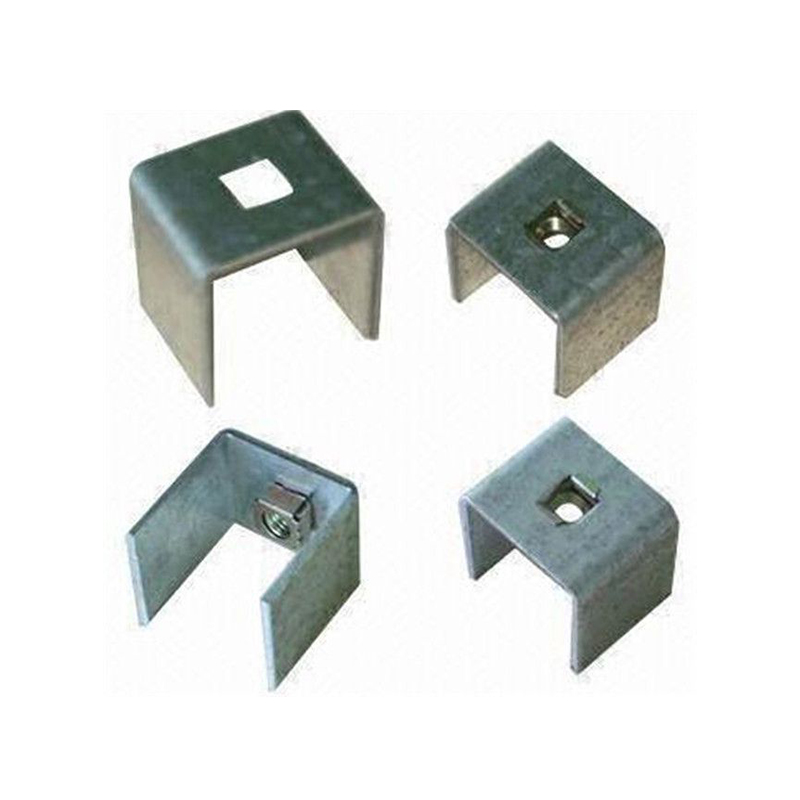

Factory manufacture china product good quality sheet metal precision metal stamping metal stamping small parts

Factory manufacture china product good quality sheet metal precision metal stamping metal stamping small parts

-

China factory custom sheet metal fabrication

China factory custom sheet metal fabrication

-

Sheet Metal Fabrication

Sheet Metal Fabrication

-

OEM custom factory precision metal stamping parts fabrication punching bending electrical auto sheet metal stamping

OEM custom factory precision metal stamping parts fabrication punching bending electrical auto sheet metal stamping

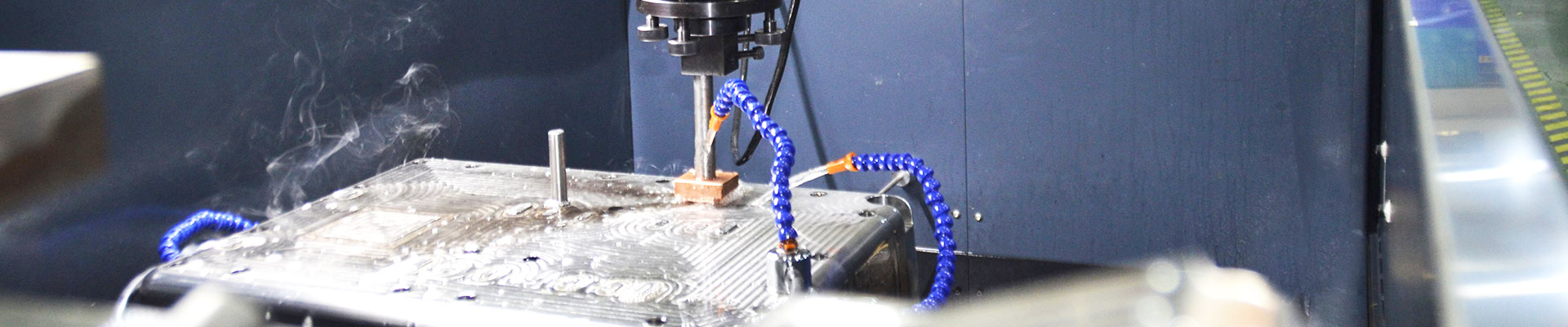

CNC Drilling

What is CNC Drilling? How does CNC Drilling work? Click on "Read More " below to find out!

Send Inquiry

Product Description

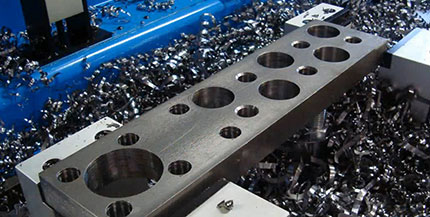

What Is CNC Drilling & How CNC Drilling Works

Drilling is a cutting process where the workpiece remains stationary, and the cutter moves instead, aligning the cutter center with the hole center, and making the cutter rotate. CNC Drilling is primarily done on CNC machines including CNC milling machines and lathes. CNC drilling service produces round holes, typically for machine screws and bolts. Drilling can process CNC drilling parts with metals, hard plastics, wood, and most other rigid materials. There are several types of drilling machines available for CNC, including upright, bench and radial drill presses. When in use, the step-by-step process for CNC drilling includes:

The operator uploads and accesses the computer-aided design (CAD) or computer-aided manufacturing (CAM) file.

The operator installs the appropriate drill bit and secures the designated material on the table.

The operator starts the drilling process through the control panel or interface.

The spindle lowers, drilling the appropriate hole diameter and depth.

CNC Drilling Services For Precision Machine Parts – China CNC Drilling Parts Factory, Supplier

Jun Ying provides the best CNC drilling services for the fabrication of both small and large series of parts of any complexity. We use various types of CNC drilling machines including upright, bench, radial, which allows us to drill holes of both simple and complex patterns up to 7 cm in diameter. The CNC drilling parts be made of metals and alloys (such as aluminum, steel, and copper) and polymers. Our drilling services provide us with the capability to complete your job in-house to our exacting quality standards. Our advanced CNC drilling equipment is integrated with our machining centers and allows us to drill your part efficiently and precisely, whether you require simple or complex drilling patterns. Our drilling services offer precision machining for complex shapes that meet all your requirements.

Accuracy:

The precision offered by MIMCNC is unmatched. It has provided companies in all industries with many returns, including raised productivity, lowered expenses, and optimized production lines.

Versatility:

One advantage of CNC drilling is the ability to use multiple bits at the same time. While operators may need to use a different type of drilling machine, they can equip that machine with a series of bits. Some machine types include a tool turret for even faster shuffling between bits.

Reproducibility:

A continuous challenge for companies across markets is producing identical batches of products. This hurdle becomes amplified for custom machining projects. With CNC, however, those challenges are solved, leading to a consistent, imperfection-free production line.

Benefits Of Our CNC Drilling Services

Increase capacity

Shorten lead times

Improve the quality & accuracy of product

Reduce installation time

Offer more complex designs

MIMCNC Drilling Surface Finishes

Along with our CNC machining services, you can opt for a wide selection of metal surface finishing services for your CNC drilling parts to improve the part's appearance, surface smoothness, corrosion resistance and other performance.

Painting: Refers to an altering surface finishing process, spraying paint, pigment, or color to a solid surface as a colored protective layer. Can be applied to metal or non-metal CNC machined components of any shape, most often applied on aluminum, stainless steel, and steel alloy parts. Painting can improve aesthetic appearance and prevent corrosion or oxidation.

Passivation: A common chemical surface treatment method for steel and stainless steel, to remove ferrous contaminants or use a light coat of protective material, to create a shell for enhancing the corrosion resistance, or reducing the chemical reactivity.

Electroplating/Plating: A process of using an electric current to reduce dissolved metal cations so that they form a thin coherent metal coating on an electrode, to change the properties of the metal surface or build up thickness for undersized parts.

Powder coat: A functional and decorative finish, which is applied as a free-flowing, dry powder, employs electrostatically and then cured under heat, to create a hard finish that is tougher than conventional paint. The main applications including household appliances, aluminum extrusions, drum hardware, automobile, motorcycle, and bicycle parts.

Anodizing: An electrolytic passivation process of forming a thin layer of aluminum oxide on the exterior of aluminum CNC machined parts to increase the thickness of the natural oxide layer and protect the metal, as the layer has higher corrosion and abrasion resistance than the untreated aluminum.

Polishing: Also known as buffing, polishing is a process of rubbing the surface of parts or utilizing a chemical action to produce a smooth and shiny surface, either giving the surface a specular reflection, or reducing diffuse reflection in some materials.

Black oxide: Also known as blackening, gun bluing or hot blackening. This is a chemical process of forming a black conversion coating on stainless steel, copper and copper-based alloys, zinc, powdered metals, silver solder, and ferrous materials, to improve corrosion resistance and minimize light reflection.

Conversion coating: Also known as chromate conversion, conversion coatings are used for metals. The surface of the metal is converted to a protective layer through the chemical or electrochemical processes, primarily used as a corrosion inhibitor, decorative finish, or to retain electrical conductivity.

Bead blasting/Bead blast: The process of removing surface deposits by applying fine glass beads at a high pressure without damaging the surface.

Abrasive blasting/sandblasting: The process or operation of propelling a stream of abrasive material composed of high-velocity sand-sizes particles against the metal surface under high pressure with blast equipment like air pressure system. Abrasive blasting can remove surface contaminants, clean metals, or increase a texture, then change the smoothness or roughness of surface.

MIMCNC also provides grinding, linishing, industrial etching, and more custom metal finishings to maximize the aesthetics and functionality of your parts.