New Products

-

Custom CNC Milling Machining Parts Perforated Sheet Metal Fabrication Aluminum Sheet Metal

Custom CNC Milling Machining Parts Perforated Sheet Metal Fabrication Aluminum Sheet Metal

-

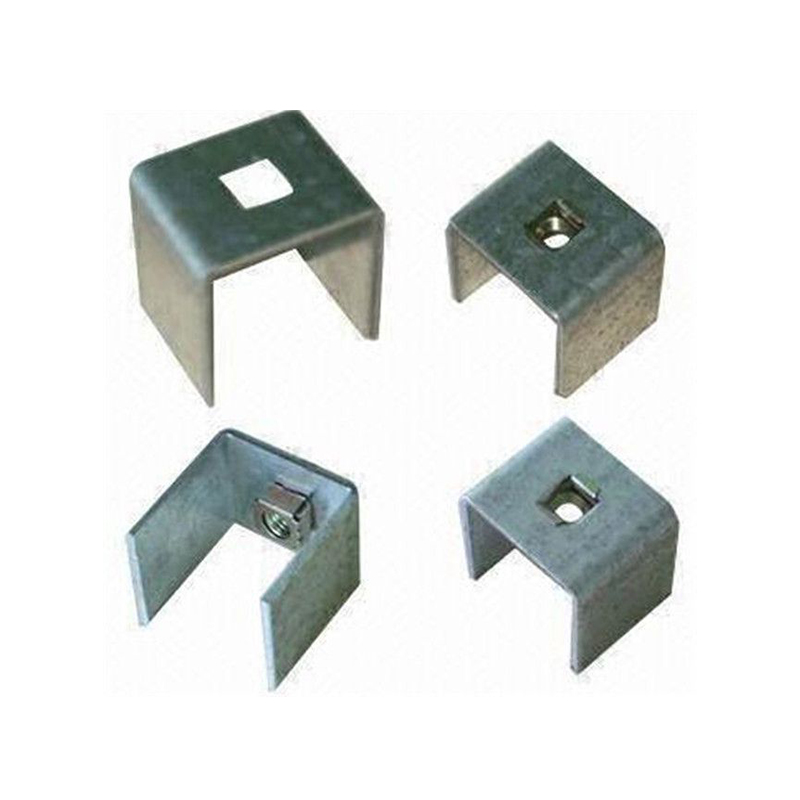

Factory manufacture china product good quality sheet metal precision metal stamping metal stamping small parts

Factory manufacture china product good quality sheet metal precision metal stamping metal stamping small parts

-

China factory custom sheet metal fabrication

China factory custom sheet metal fabrication

-

Sheet Metal Fabrication

Sheet Metal Fabrication

-

OEM custom factory precision metal stamping parts fabrication punching bending electrical auto sheet metal stamping

OEM custom factory precision metal stamping parts fabrication punching bending electrical auto sheet metal stamping

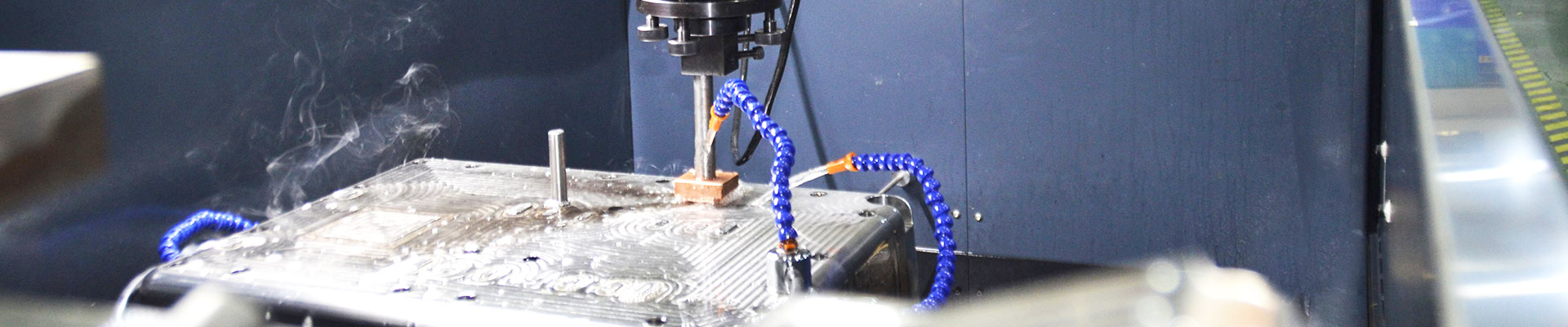

CNC Milling

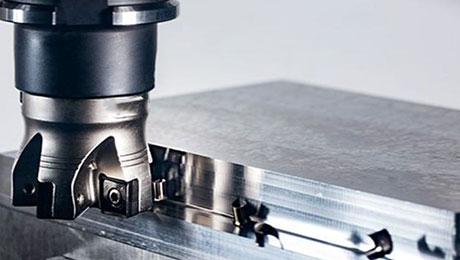

Advanced Precision CNC Milling Services – China Top CNC Milled Parts Manufacturer

Send Inquiry

Product Description

Advanced Precision CNC Milling Services – China Top CNC Milling/Milled Parts Manufacturer

Looking for low cost CNC milling parts with unparalleled quality? MIMCNC Metal Manufacturing is a professional China CNC company which provides superior precision CNC milling services with advanced machines. Our services include CMC milling center and milling machining centers, with both 3 and 5 axis machines.

Our experienced operators proficient in CAD (computer-aided design) and CAM (computer-aided manufacturing) programs are always finding the best way to produce the highest quality CNC milled parts & components for clients. With strong capabilities and extensive experience in the industry, we can provide top-grade and cost-effective custom CNC milling services from China.

Our milling equipment allows for fast manufacturing, rapid prototyping, and high precision. Our high-quality rapid CNC milling products are used in the automation design, lockset, automobile parts machining, machinery milling, defense industry, medical equipment, lighting parts machining industries.

Send your inquiry or drawing today to get an online CNC quote!

MIMCNC Milling Services Capabilities

With decades of experiences and expertise in CNC machining services, we providing OEM milling service and products involving precision milling, thread milling, metal milling, plastic milling, etc.

There are six advanced CNC machines at the MIMCNC Milling Center:

Number of axes: 3-axis or 5-axis

Product dimension for 3-axis milling machines: up to 500 x 500

Product dimension for 5-axis milling machines: up to 300 diameter

Why Choose MIMCNC Milling Services

High Precision Production. Mimcnc custom CNC milling parts in tolerances ranging from +/-0.001″ – 0.005″, custom design depending on customer specs

Extensive Material Option. Wide variety of certified materials (over 50 metal and plastic materials) and surface finishes available

Profitable Custom Design. Precise design and produce to custom specifications, offer clients the most cost and time saving CNC milling service

Rapid prototyping. Get prototypes quickly, optimize the entire high-speed milling workflow with advanced milling machines and full equipped CNC milling factory

What is CNC Milling & How Does CNC Milling Work

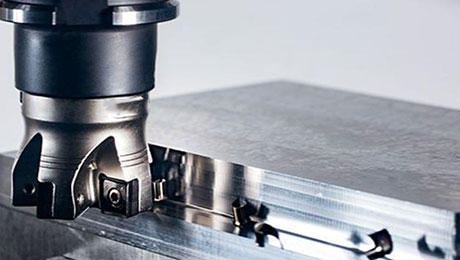

CNC milling (computer numerical control milling) is a CNC machining process that involves removing material from the workpiece by rotating and moving a cutting tool, such as a milling cutter, and positioning the workpiece properly, to produce or finish a custom CNC machining object. CNC milling technique can be used to shape apart from beginning to finish, it’s best to produce features or definitions as a secondary or finishing process for machined components. The milling cutting tool can be placed horizontally or vertically, but since the numerically controlled milling machines have improved much in recent years, moving on several axis, up to 5 axes, allows the machine to put more features into a part.

CNC Milling Process – What is the Process of CNC Milling?

Starting from designing a CNC milling part drawing or geometry with CAD software, then CAM software converts the file to CNC machine program, which can dictate the machine what to do and how to do. CNC milling services apply computerized technique to complete the manufacturing as the following basic production stages:

Designing a CNC Milling CAD model

Convert the CAD model into a CNC milling program

Setting up the CNC milling machine

Cutting small pieces off the block material to obtain approximate shape

Executing the CNC milling operation to finish the part

CNC Milling Operations (Types) – What Does A CNC Mill Do

CNC milling service, one type of CNC machining service, is ideal for manufacturing CNC milled parts with high accuracy and tight tolerances in prototype or small and large production batches. It is achieved through one of the following common CNC milling operations:

Plane Milling: Also called surface or slab milling, plane milling refers to the milling operation utilize plane milling cutters with teeth on the periphery to perform the cutting, the axis of rotation of the cutting tool is parallel to the workpiece surface.

Face Milling: This operation uses milling cutters have teeth both on the periphery and tool face, the rotating axis of cutting tool is perpendicular to the surface of the workpiece, generally for producing flat surfaces and contours.

Form Milling: Uses form cutting tools or fly cutters for specific purposes, including convex, concave cutters, typically for creating irregular surfaces and contours like curved surfaces.

Angular Milling: also written a angle milling, milling flat surfaces which are neither parallel nor perpendicular to the axis of the cutter.

Gear Milling: the milling process for creating a gear.

Thread Milling: the interpolation of a thread mill around or inside a workpiece to create a desired thread, requires machines capable of moving on the X, Y, and Z axis simultaneously.

Profile Milling: rough or finish mill vertical or slanted surfaces, continuous tool path.

Straddle Milling: machine two or more parallel vertical surfaces at a single cut.

Other milling operations: Gang Milling, Side Milling, End Milling, Saw Milling, Helical Milling, Cam Milling, Milling Keyways, Grooves and Slot.

CNC Milling Machines – What Is A CNC Mill & Types of Milling Machines

CNC milling machines uses a rotating cylindrical tool (milling cutter) held in a spindle to perform the milling operations, for getting a wide array of shapes, slots, holes, and other necessary impressions. As a common Computer Numerical Control machine, CNC mill can cut in different angles and move along several axes, allows a variety of milling parts features and designs. The workpiece on CNC mill can be moved across the tool in certain direction.

There are different types of CNC mills, categorized based on the number of axes:

2-axis CNC milling machine: Cut holes and slots in the x- and z-axes

3-axis CNC milling machines: Added y-axis, can cut vertically and in any direction

4-axis CNC milling machines: Add the ability to rotate the x-axis, similar to a lathe.

5-axis CNC milling machines: Most complete milling machine, incorporate rotation in both the x- and y-axes.

MIMCNC Milling Surface Finishes

MIMCNC provides an array of surface finishing services for your metal CNC milling parts to improve the parts appearance, surface smoothness, chemical, corrosion resistance, and other properties.

Painting: Refers to an altering surface finishing process, spraying paint, pigment, or color to a solid surface as a colored protective layer. Can be applied to metal or non-metal CNC machined components of any shape, most often applied on aluminum, stainless steel, and steel alloy parts. Painting can improve aesthetic appearance and prevent corrosion or oxidation.

Passivation: A common chemical surface treatment method for steel and stainless steel, to remove ferrous contaminants or use a light coat of protective material, to create a shell for enhancing the corrosion resistance, or reducing the chemical reactivity.

Electroplating/Plating: A process of using an electric current to reduce dissolved metal cations so that they form a thin coherent metal coating on an electrode, to change the properties of the metal surface or build up thickness for undersized parts.

Powder coating/Powder coat: A functional and decorative finish, which is applied as a free-flowing, dry powder, employs electrostatically and then cured under heat, to create a hard finish that is tougher than conventional paint. The main applications including household appliances, aluminum extrusions, drum hardware, automobile, motorcycle, and bicycle parts.

Anodizing/Anodized: An electrolytic passivation process of forming a thin layer of aluminum oxide on the exterior of aluminum CNC machined parts to increase the thickness of the natural oxide layer and protect the metal, as the layer has higher corrosion and abrasion resistance than the untreated aluminum.

Polishing: Also known as buffing, polishing is a process of rubbing the surface of parts or utilizing a chemical action to produce a smooth and shiny surface, either giving the surface a specular reflection, or reducing diffuse reflection in some materials.

Black oxide: Also known as blackening, gun bluing or hot blackening. This is a chemical process of forming a black conversion coating on stainless steel, copper and copper-based alloys, zinc, powdered metals, silver solder, and ferrous materials, to improve corrosion resistance and minimize light reflection.

Conversion coating: Also known as chromate conversion, conversion coatings are used for metals. The surface of the metal is converted to a protective layer through the chemical or electrochemical processes, primarily used as a corrosion inhibitor, decorative finish, or to retain electrical conductivity.

Bead blasting/Bead blast: The process of removing surface deposits by applying fine glass beads at a high pressure without damaging the surface.

Abrasive blasting/sandblasting: The process or operation of propelling a stream of abrasive material composed of high-velocity sand-sizes particles against the metal surface under high pressure with blast equipment like air pressure system. Abrasive blasting can remove surface contaminants, clean metals, or increase a texture, then change the smoothness or roughness of surface.

We also provides grinding, linishing, industrial etching, and more custom metal finishings to maximize the aesthetics and functionality of your parts.