New Products

-

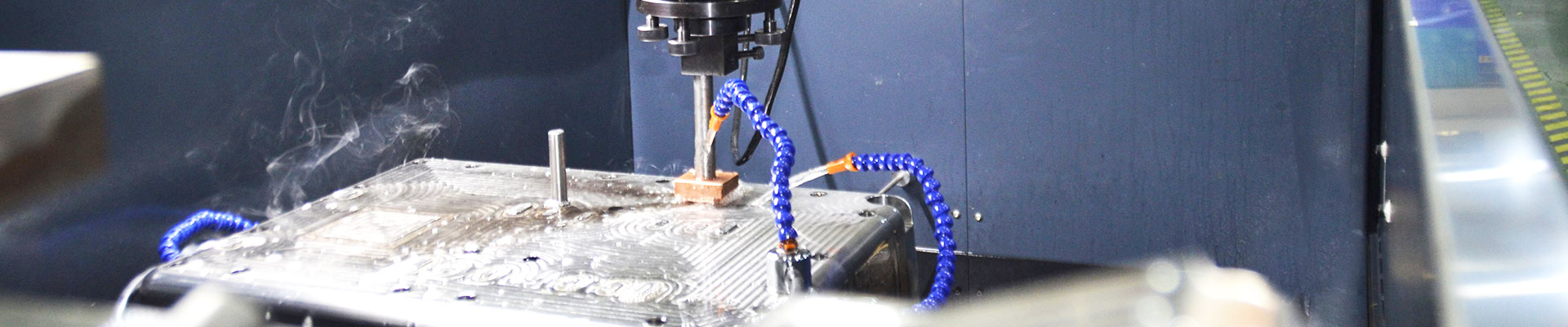

Custom CNC Milling Machining Parts Perforated Sheet Metal Fabrication Aluminum Sheet Metal

Custom CNC Milling Machining Parts Perforated Sheet Metal Fabrication Aluminum Sheet Metal

-

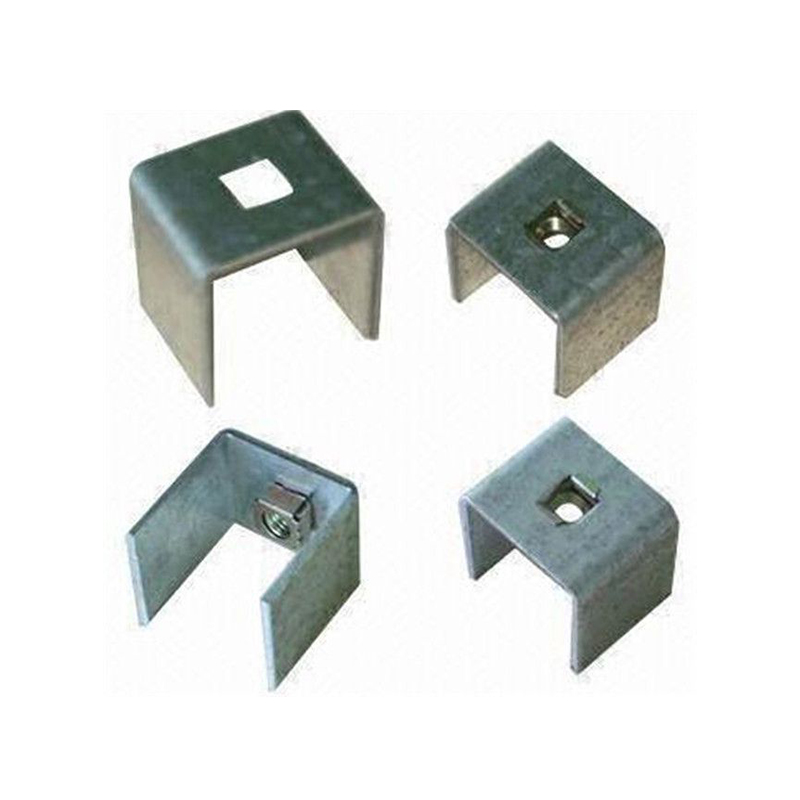

Factory manufacture china product good quality sheet metal precision metal stamping metal stamping small parts

Factory manufacture china product good quality sheet metal precision metal stamping metal stamping small parts

-

China factory custom sheet metal fabrication

China factory custom sheet metal fabrication

-

Sheet Metal Fabrication

Sheet Metal Fabrication

-

OEM custom factory precision metal stamping parts fabrication punching bending electrical auto sheet metal stamping

OEM custom factory precision metal stamping parts fabrication punching bending electrical auto sheet metal stamping

CNC Turning

Custom CNC Turning Services – OEM China CNC Turning Parts Manufacturer & Company

Send Inquiry

Product Description

Custom CNC Turning Services – OEM China CNC Turning Parts Manufacturer & Company

MIMCNC is an experienced precision CNC turning supplier, manufacturer, and exporter in China. We specialize in offering the best OEM CNC lathe services of superior quality at a low price, with the operation of an impressive range of state-of-the-art turning machines. We can manufacture CNC lathe parts or high precision machined components, such as washers, bolts, shafts, rivets, spacers, sleeves, nipples, stainless steel fittings, pipe fittings, light fittings, wheel studs, etc. Our advanced CNC turning center routinely works with a wide variety of materials, including copper, brass, stainless steel, carbon steel, aluminum, and titanium. We can always choose a suitable precision turning process to meet your requirements. Our custom CNC machining services ensure that our customers receive the highest quality CNC turned parts. Send your inquiry or drawing online today to receive a quote.

MIMCNC Precision CNC Turning Capabilities and Features:

MIMCNC (mincnc.com) is capable of providing cost-effective CNC turning lathe services and quality products with high precision and accuracy for a wide variety of applications:

Capability to run low, medium, or high-volume batches

Rapid prototyping and end-use manufacturing

High dimensional accuracy, high speed and high reliability

Wide selection of compatible metal and plastics materials

Great productivity and improved efficiency

Smooth finishes and tight tolerances can be achieved

Why Choose MIMCNC Turning Services

We have multiple CNC manufacturing capabilities and can meet a wide variety of needs. In addition to turning, we specialize in milling, lathing, drilling, CNC turning and milling services. Our trusted team offers a wide selection of processes to meet your specific needs.

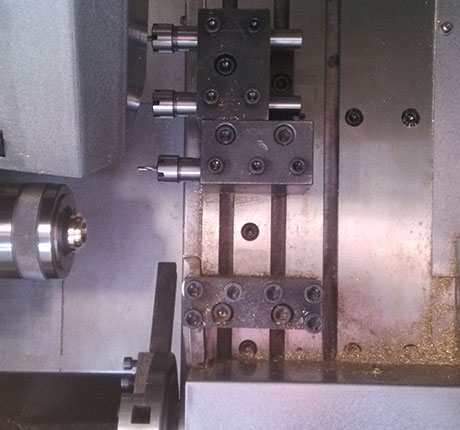

We have a complete set of state-of-the-art turning equipment and quality control system in the CNC shop, to deliver durable lathe parts with affordable CNC turning prices.

Our technicians are experts in the field of CNC turning, and have rich experience in providing custom services to a wide range of industries; both domestically and internationally.

What Is CNC Turning Service & How CNC Turning Works – CNC Turning Process Basics

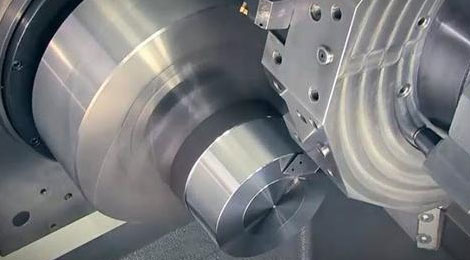

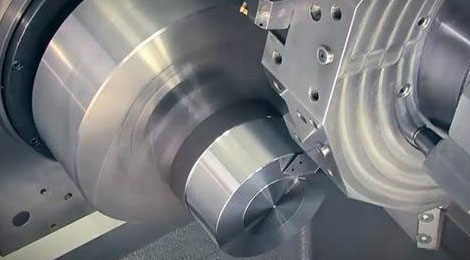

CNC turning is a particular form of the precision CNC machining process that holds a cylindrical workpiece in a chuck and rotated, while the cutting tool is fed to the piece and removing material to get the desired CNC turned components. This process leaves an excellent surface finish that sometimes requires no post-processing. Turning can be performed on the outside or inside of the workpiece to produce tubular components to diverse geometries.

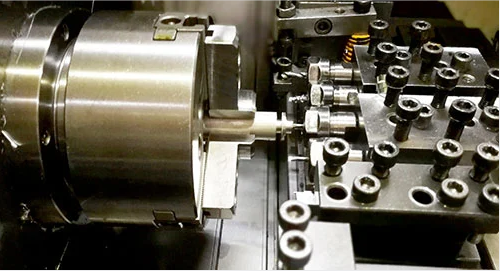

When it comes to the CNC turning process, the subtractive manufacturing method is typically performed on CNC lathe or turning center. Before the cutting, G-code and turning machine need to be prepared, then secure the blank bar of stock material in the chuck of spindle, the chuck holds the piece in place when the spindle rotates. With the spindle spins to a certain speed, a stationary single-point CNC turning cutter will move on a linear path that parallel to the axis of rotation and remove excess material, reduce the diameter of the block, specify the dimension, and create smooth finish, to get final custom CNC turned parts with desired specification.

What is the CNC Turning Center? – Differences between CNC Lathe and Turning Center

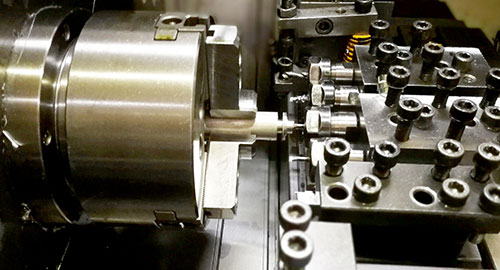

CNC turning center, the equipment or machines for CNC turning service, is a computer controlled 3, 4 or 5-axis machine has capabilities of turning, drilling, tapping, and milling, using live tools with powered rotary tool turret, dual spindles, Y-axis, and multiple turrets. The CNC lathe is a simpler 2-axis machine with one spindle, basically composed of headstock, carriage, tailstock, and bed.

CNC turning centers have more complex structure than CNC lathes.

CNC turning centers has higher production capabilities and versatility than CNC lathes.

CNC lathes are generally flat-bed type while turning center usually slant-bed type.

There are only minimal protective enclosure around the lathe, while the turning center is commonly equipped with full enclosures to keep chips and coolant splashes within the machine.

CNC Turning Operations – Types of CNC Turning

There are many types of CNC turning operations for CNC lathe services can be performed on a live tooling lathe in CNC turning factory. Below is a list of all our processes, which all vary in with tool use, cost, and set-up time:

Tapered turning: Produce a cylindrical part where the diameter decreases from one end to the other.

Hard turning: Suited for materials with a Rockwell C hardness greater than 45, typically performed after heat treatment.

Spherical generation: Create a spherical finished surface, turning around fixed rotary axis.

Facing: A turning operation in which the workpiece is machined to its center.

Parting: Create deep grooves that remove a completed or partially complete component from its parent stock.

Grooving: Similar to parting, but only cut to a specific depth from outside or inside of workpiece.

Drilling: Remove materials to drill holes from the inside of a workpiece with drill bits held stationary in the tail stock or tool turret of the lathe.

Boring: Enlarge or smooth an existing hole.

Knurling: Cut a serrated pattern onto the surface of workpiece with a knurling tool, to enhance visual appearance or make the part easier to grip.

Reaming: remove a small volume of materials from a drilled hole, for highly accurate diameters.

Threading: turn standard and non-standard screw threads, generally refersto single-point threading.

Polygonal turning: non-circular forms machining operation without interrupting the rotation of the raw material.

CNC Turning Materials – Materials Used for CNC Lathes

CNC turning service can be applied on a wide variety of materials, including metal, plastic, and wood. Different lathes are needed for turning metal and wood. According to the types of materials machined, certain maintenance and safety precautions may be required for the lathe. Below are some common materials used by CNC turning manufacturer:

Metals: aluminum, magnesium, steel, stainless steel, brass, copper, bronze, titanium, nickel alloy, etc.

Plastics: nylon, polycarbonate, POM, ABS, etc.

Applications of CNC Turning Services and Parts

MIMCNC is a CNC turning company offering services suitable for mass production of high precision small CNC turning parts, such as components for cell phones, medical devices, optical equipment, automobile, lighting industry, office equipment, and more. We can know that CNC turning has become one of the most basic, extensive, and important technologies in the mechanical manufacturing industry, which directly affects production efficiency, cost, energy consumption, and environmental protection.