New Products

-

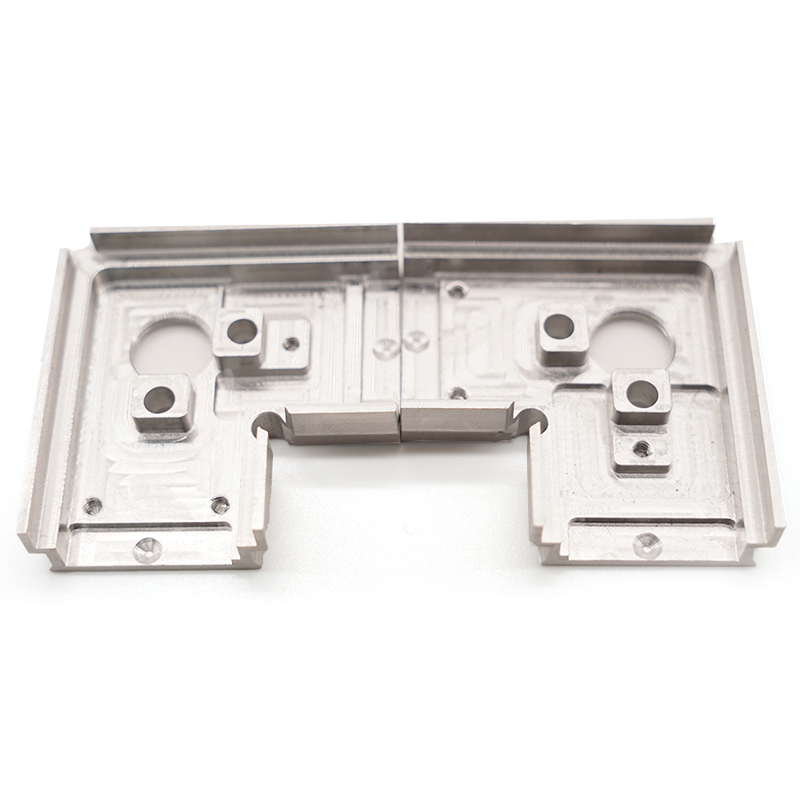

Custom CNC Milling Machining Parts Perforated Sheet Metal Fabrication Aluminum Sheet Metal

Custom CNC Milling Machining Parts Perforated Sheet Metal Fabrication Aluminum Sheet Metal

-

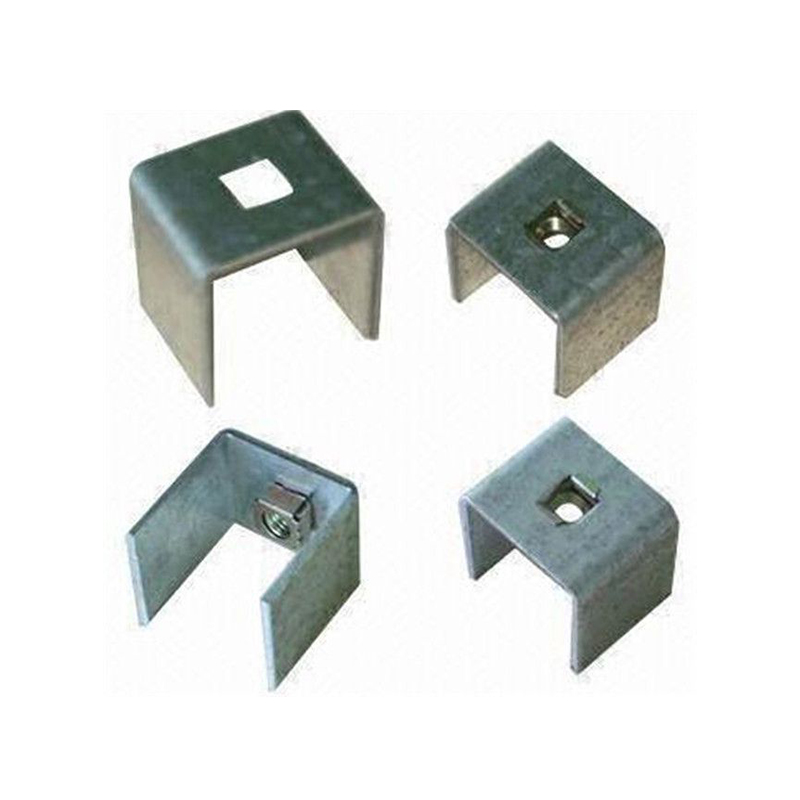

Factory manufacture china product good quality sheet metal precision metal stamping metal stamping small parts

Factory manufacture china product good quality sheet metal precision metal stamping metal stamping small parts

-

China factory custom sheet metal fabrication

China factory custom sheet metal fabrication

-

Sheet Metal Fabrication

Sheet Metal Fabrication

-

OEM custom factory precision metal stamping parts fabrication punching bending electrical auto sheet metal stamping

OEM custom factory precision metal stamping parts fabrication punching bending electrical auto sheet metal stamping

Precision Machining

Precision Machining Services Company – CNC Precision Machining Parts Manufacturer If you need to take your design to an outstanding level for a specific industry

Send Inquiry

Product Description

Precision Machining Services Company – CNC Precision Machining Parts Manufacturer

If you need to take your design to an outstanding level for a specific industry, ordinary CNC machining may be not able to meet the requirements, precision machining can be the best solution. Mimcnc is a precision machining company that has the ability to follow specific blueprints made by CAD and CAM software, and create a wide variety of products, parts, components, and objects with repeatability and well-controlled tolerances. Our precision machining services allow a diversity of materials such as plastics, steel, bronze, brass, aluminum, etc., depending on the sizes, shapes, and characteristics of the CNC precision machining parts. Various advanced precision machining tools and techniques are used. The combination of different equipment is popular in order to get the job done efficiently. Precision CNC machining at mimcnc will help you ensure that these parts can not only be manufactured precisely, but also be produced repeatedly with this accuracy.

Why Choose MIMCNC Precision Machining Services

Can handle any production volume requirement ranging from prototypes to mass production

Parts can be machined to the same close tolerances from part to part repeatedly

Most precision measuring and cutting to precision parts with exact specifications

Various CNC machining and precision machining facilities and setups to ensure capability

High flexibility allows us to tackle intricate complex design and take it to market

Precision Machining Services at MIMCNC – Precision Machining Technology

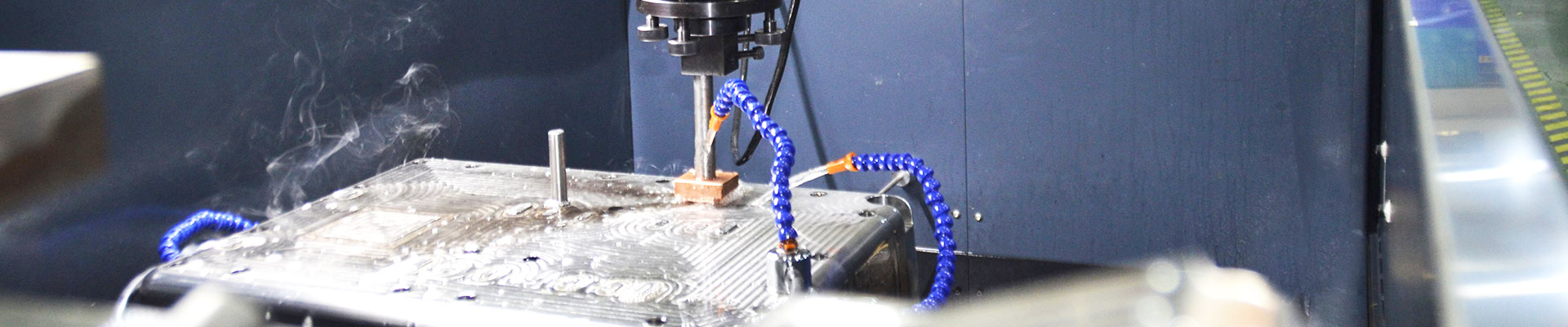

CNC Machining: in CNC precision machining, CAD software is used to create the digital design of the desired part, which will be translated into a programmed file by CAM software to instruct the machine tools on how to execute the operations. Commonly adopted CNC machining equipment are CNC lathes and CNC milling machines. Techniques involved in CNC precision machining including milling, turning, drilling, boring, reaming, tapping, etc.

Swiss Machining: precision Swiss machining applies a Swiss-type machine that is designed to bring the raw material to the tool, it allows multiple operations to be done simultaneously in different zones and provides a high degree of precision, Swiss machining is very ideal for the production of components used in robotics, surgical, medical, aerospace, electronics, precision tooling and more industries where superior precision is required.

Multi-axis Machining: CNC machines are constantly being improved to gain higher capabilities, one of the most significant ways is the movement direction of multiple axes. Multi-axis machining such as 5-axis precision machining can perform more than three axes of movement, and increase part accuracy, surface finish, and produce more complex parts in a single setup.

Materials Available for Precision Machining Services

Our precision machining service works with a number of materials including metals, alloys, plastics, and other choices to produce high-quality precision machined components.